Experts in advanced filtration systems for metal cutting, grinding, and honing machines. CutEdge specializes in coolant filtration, chip conveyors, oil skimmers, and temperature control systems.

Our comprehensive solutions improve machine efficiency, extend tool life, and maintain optimal coolant quality for superior machining performance.

Complete filtration and coolant management systems

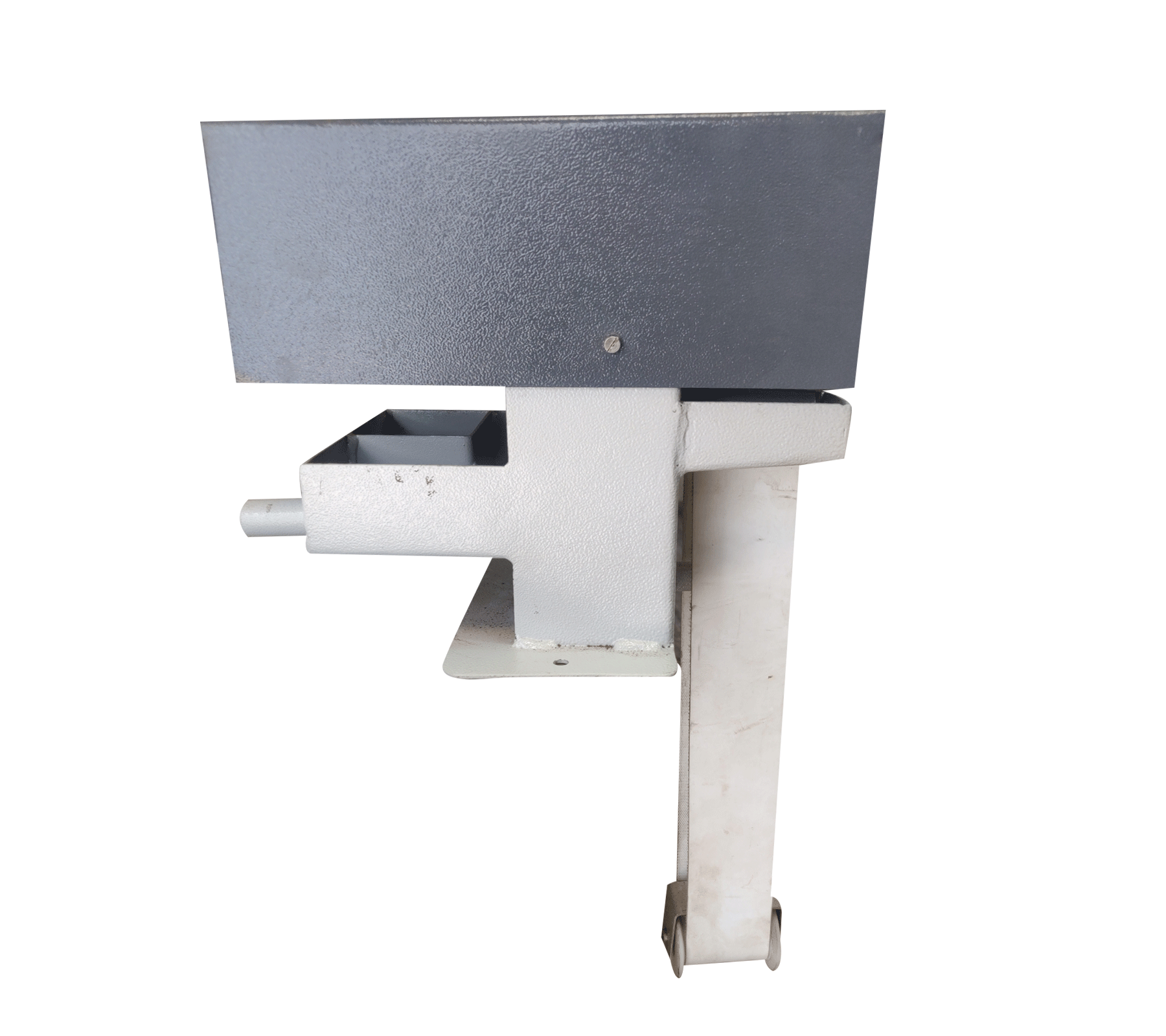

Heavy-duty chip conveyor featuring both belt and roller mechanisms for efficient removal of metal chips and swarf from CNC machines. The dual-system design ensures reliable handling of various chip sizes and types.

CNC machines, grinding & metal cutting operations

Dual belt/roller system, heavy-duty construction, mobile design

Efficient chip conveyor designed for automatic collection and transport of metal chips from machine tools. Ensures continuous chip removal, improves cleanliness, and maintains a safe working environment.

CNC machines, machining centers, production lines

Continuous operation, improved safety, low maintenance

Efficient oil skimmer designed to remove tramp oil and floating contaminants from coolant tanks and sumps. The belt-type mechanism continuously removes oil from the surface, maintaining coolant quality and extending its lifespan.

Coolant tanks, machine sumps, oil separation

Extends coolant life, reduces costs, continuous operation

Comprehensive coolant filtration system featuring a compact band filter design with integrated control panel. Provides continuous filtration of metalworking fluids, removing particles and chips to maintain coolant cleanliness.

Continuous band filtration with automatic indexing

Integrated control panel, compact design, improves tool life

High-efficiency magnetic separator designed to remove ferromagnetic particles and chips from coolant. The powerful magnetic system attracts and separates iron and steel particles, preventing machine damage and maintaining coolant purity.

Ferrous particle removal, coolant filtration, chip separation

Protects pumps, removes fine particles, low maintenance

Advanced magnetic roller separator featuring powerful drum design for continuous removal of ferromagnetic chips and particles. Ideal for high-volume coolant processing applications with automatic self-cleaning operation.

Magnetic roller with automatic cleaning mechanism

High separation efficiency, continuous operation, self-cleaning

Additional filtration and handling solutions available

For detailed specifications and pricing on these products

Contact Our TeamOur experts can design and implement a complete coolant management system tailored to your specific machining requirements and production environment.